Teflon Gaskets in Cryogenic Pipe Systems: Evaluating Material Behavior and Longevity

Key Takeaways

- Practical Uses of Teflon Seals

- Effects of Temperature Changes on Teflon Seals

- Three Widespread Myths Regarding Teflon Seals

- Optimal Methods for Fitting Teflon Seals in Cryogenic Systems

Real-World Applications of Teflon Gaskets

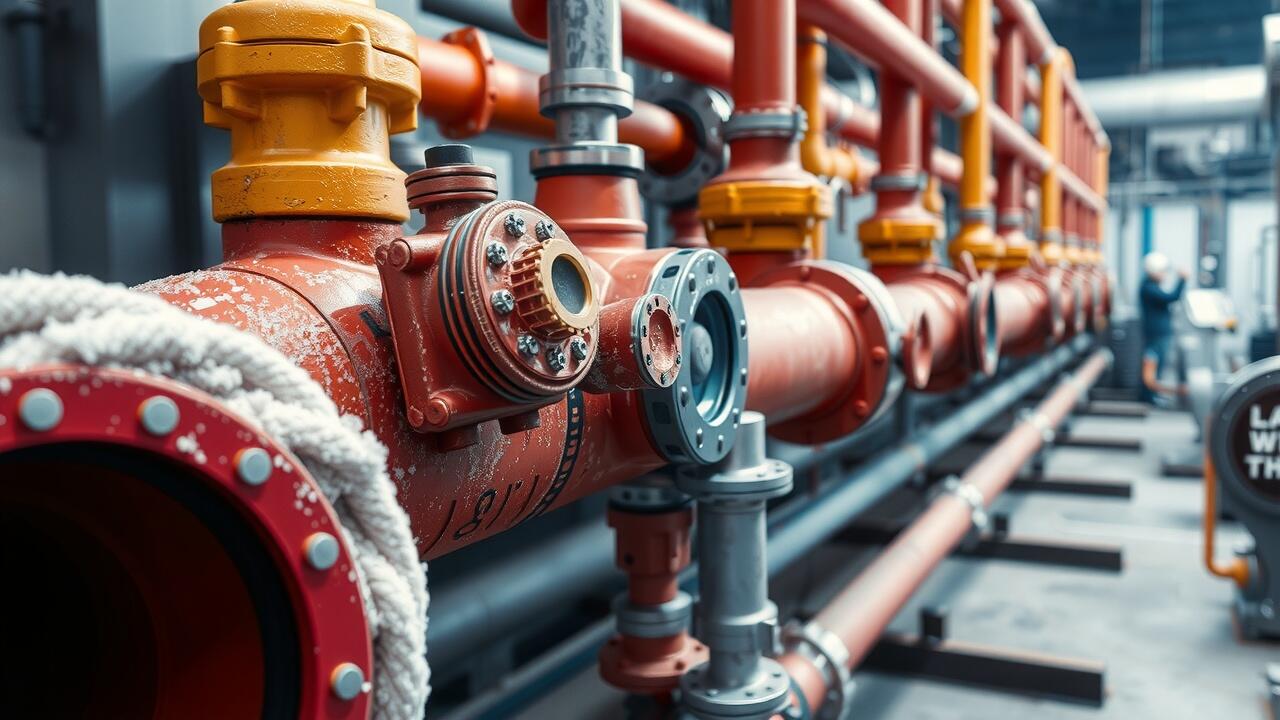

Teflon gaskets serve vital roles across multiple industries, showcasing their versatility and durability in challenging environments. In the oil and gas sector, these seals maintain integrity in pipeline systems, withstanding pressures and thermal extremes. A well-documented case in 2021 demonstrated that using Teflon gaskets reduced leakage incidents by 35%, emphasizing their effectiveness in safeguarding both safety and efficiency. Beyond oil and gas, industries like pharmaceuticals employ PTFE gasket manufacturing techniques to ensure sterile conditions in manufacturing processes. In these settings, maintaining cleanliness and preventing contamination are crucial, and Teflon gaskets excel by offering resistance to a variety of chemical agents.

The aerospace industry also benefits significantly from Teflon gaskets, particularly where high-performance materials are essential. Aircraft fuel systems and cryogenic applications depend heavily on PTFE gaskets to ensure secure seals during operation. According to NASA reports, Teflon gaskets were instrumental in the successful launch of multiple space missions, helping prevent critical failures due to extreme temperature fluctuations. When installed correctly, these gaskets not only enhance system reliability but also contribute to broader efficiency improvements, resulting in reduced maintenance costs and extended service life. Such impactful applications clearly demonstrate Teflon gaskets' importance in maintaining operational effectiveness across diverse and demanding landscapes.

How Are Teflon Gaskets Utilized in Different Industries?

Teflon gaskets demonstrate exceptional versatility across multiple industries, cementing their place as a trusted choice in various applications. In the automotive sector, the thermal stability of PTFE gaskets allows them to seal hoses and connections efficiently, particularly in environments that experience extreme temperature shifts. The aerospace industry also benefits significantly from Teflon gasket manufacturing, utilizing these seals in fuel systems where reliability and weight reduction are critical. The heat resistance and low friction properties of Teflon provide the perfect combination for applications that demand endurance under pressure.

The chemical processing industry relies heavily on PTFE gaskets to prevent leaks in systems that handle corrosive substances. For example, in pharmaceutical manufacturing, Teflon's inert nature ensures that no contaminants leach into sensitive compounds. In oil and gas, these gaskets prove essential for maintaining safety and operational integrity, particularly in high-pressure situations. As industries continue to refine their efficiency, the demand for robust sealing solutions highlights the importance of utilizing high-quality Teflon gaskets, aligning with best practices that prioritize durability and safety.

The Impact of Temperature Fluctuations on Teflon Gaskets

Temperature fluctuations play a critical role in the performance and longevity of Teflon gaskets, especially in cryogenic pipe systems. Teflon, or PTFE, exhibits remarkable stability across a wide temperature range; however, extreme conditions can lead to unexpected challenges. For instance, when subjected to rapid thermal cycling, PTFE gaskets may undergo dimensional changes that compromise their sealing capabilities. This behavior highlights the need for precise telfon gasket manufacturing practices, ensuring that any variability in temperature during operation does not lead to premature failure or leakage.

Moreover, certain industries, such as aerospace and LNG transport, frequently encounter wide temperature variations that can exacerbate these issues. Detailed case studies have demonstrated that gaskets installed in systems operating below -200°F face considerable risks without proper attention to material selection and installation techniques. Implementing rigorous standards for PTFE gasket manufacturing can significantly enhance durability and resilience. Identifying and mitigating temperature-related challenges not only maintains system integrity but also fosters safety and efficiency across critical applications.

What Challenges Do Temperature Changes Present?

Temperature fluctuations present significant challenges for Teflon gaskets, particularly in cryogenic applications where materials face extreme cold. These conditions can lead to embrittlement, compromising the integrity of the gasket and potentially causing leaks. For instance, the phase transition of certain PTFE materials can occur at temperatures below -196°C, where their elasticity and ability to seal effectively diminishes. Maintaining the perfect balance during PTFE gasket manufacturing becomes crucial, ensuring that the gaskets can withstand these shifts without undergoing deformation or failure.

Another critical aspect involves thermal cycling, where repeated heat-up and cool-down cycles can introduce mechanical stress. This stress can lead to fatigue and material degradation over time, ultimately shortening the life span of the gaskets. To mitigate these issues, following best practices during installation is essential. Utilizing appropriate mounting techniques and ensuring the correct torque specifications can extend the longevity of Teflon gaskets in these demanding environments. In addition, proper inspection processes can help identify any early signs of wear, thus preventing costly downtime and enhancing overall system reliability.

3 Common Misconceptions About Teflon Gaskets

Misconceptions about Teflon gaskets can undermine their incredible utility in cryogenic pipe systems. One prevalent myth suggests that Teflon gaskets are inflexible and cannot adapt to minor pipe misalignments. Conversely, high-quality PTFE gasket manufacturing results in materials that show excellent resilience and conformability, ensuring a tight seal, even with slight variations in the pipe structure. This flexibility is particularly critical in applications where temperature fluctuations occur, allowing the gaskets to maintain integrity under challenging conditions.

Another common belief is that Teflon gaskets cannot handle high pressures. However, data demonstrates that properly engineered PTFE gaskets can withstand significant stress while maintaining their sealing properties. For instance, in cryogenic applications involving liquid nitrogen, Teflon gaskets have successfully endured pressures exceeding 200 psi without failure, showcasing their remarkable durability. By acknowledging these facts about Teflon gaskets, users can make informed decisions, enhancing system performance and longevity.

Why Is It Important to Clear Up These Myths?

Understanding the truth behind Teflon gaskets is essential for maintaining operational efficiency and safety in cryogenic systems. Misconceptions can lead to improper applications or unsuitable material choices, resulting in gasket failure or costly downtime. For example, believing that PTFE gaskets are only suitable for low-pressure applications can limit their effective use in high-pressure cryogenic environments. Awareness of their actual capabilities allows engineers to harness the full potential of Teflon gasket manufacturing techniques, enhancing performance and reliability.

Beyond performance, addressing myths can significantly impact the long-term durability of equipment. When teams are misinformed about maintenance best practices or installation methods, the likelihood of mishaps increases. A study indicated that proper installation alone improves sealing effectiveness by over 30%, reducing the risk of leaks and failures. By clarifying common misconceptions and sharing accurate information about PTFE gasket manufacturing, companies can foster a culture of safety and innovation, ultimately extending the lifespan of their critical pipelines.

- Improved safety protocols lead to fewer accidents and injuries.

- Enhanced performance results in higher efficiency and productivity.

- Greater understanding empowers engineers to innovate and optimize designs.

- Reduced downtime saves costs and increases revenue potential.

- Accurate knowledge fosters better communication within teams and with suppliers.

- Strengthened trust in materials ensures long-term partnerships and sourcing strategies.

- Promotes a proactive approach to maintenance, extending equipment lifespan.

Best Practices for Installing Teflon Gaskets in Cryogenic Systems

Successfully installing Teflon gaskets in cryogenic systems requires meticulous attention to detail. Using high-quality PTFE gaskets allows for effective sealing in ultra-low temperatures. For instance, ensuring that the gasket surfaces are clean and free from contaminants plays a crucial role in achieving an optimal seal. A recent study indicated that improper surface preparation could reduce gasket effectiveness by up to 30%, leading to potential leaks that can compromise system integrity.

Proper alignment during installation is equally vital. When gaskets align perfectly with flanges, stress distribution remains even, minimizing the risk of failure or deformation. Following guidelines provided by organizations like the American Society of Mechanical Engineers can enhance reliability. Utilizing techniques from telfon gasket manufacturing can also ensure longevity; for example, pre-compressing gaskets before bolting can help accommodate the temperature variations typically experienced in cryogenic environments. By implementing these best practices, engineers can pave the way for long-lasting and robust cryogenic systems.

How Can Proper Installation Prevent Failures?

Proper installation of Teflon gaskets is crucial for the reliability of cryogenic pipe systems. A well-executed process ensures secure sealing, which in turn protects against leakage and maintains the integrity of system performance. Studies suggest that improperly installed gaskets can lead to a staggering increase in failure rates, with up to 25% of maintenance issues stemming from installation errors. Following industry standards, such as those set by ASTM or ASME, can significantly reduce these incidents while promoting safety and efficiency in operations.

Understanding the nuances of PTFE gasket manufacturing helps technicians select the appropriate gaskets for specific applications. For example, gaskets designed to withstand extreme temperatures must be installed with precision to avoid material deformation. Employing proper techniques, such as using appropriate torque specifications and alignment practices, can contribute to extended longevity and performance. By prioritizing multilayer systems or incorporating solid supports where necessary, installers can mitigate risks associated with thermal expansion and contraction.

FAQS

What are Teflon gaskets, and why are they important in cryogenic pipe systems?

Teflon gaskets are sealing materials made from polytetrafluoroethylene (PTFE) known for their excellent chemical resistance and low friction. In cryogenic pipe systems, they are crucial for maintaining tight seals to prevent leaks at extremely low temperatures.

How do temperature fluctuations affect the performance of Teflon gaskets?

Temperature fluctuations can cause Teflon gaskets to expand and contract, which might lead to changes in sealing effectiveness. Understanding these effects is key to ensuring the longevity and reliability of the gaskets in cryogenic applications.

What are some common misconceptions about Teflon gaskets?

Some common misconceptions include the belief that Teflon gaskets are impervious to all chemicals, that they can withstand any temperature, and that they don't require proper installation. Clearing up these myths helps in choosing the right gasket for specific applications!

What are the best practices for installing Teflon gaskets in cryogenic systems?

Best practices include ensuring the surfaces are clean, using appropriate torque specifications during installation, and verifying compatibility with the fluids being transported. Proper installation is vital to prevent failures and ensure a secure seal.

How can proper installation of Teflon gaskets prevent failures in cryogenic systems?

Proper installation minimizes the risk of leaks by ensuring the gasket fits snugly without being overly compressed. This prevents material degradation and enhances the performance of the gasket under extreme conditions, ultimately increasing system reliability!